A Method to Reduce the Toxicity of 3D-Printed Parts

Decrease toxicity Maintain integrity and appearance Simple, accessible, cheaper

3D printersAutomotive industry (specialized components, prototypes)Healthcare & life sciences industry (implants, stents, prosthetics)Consumer industry (apparel, fashion accessories)

None

20170120523

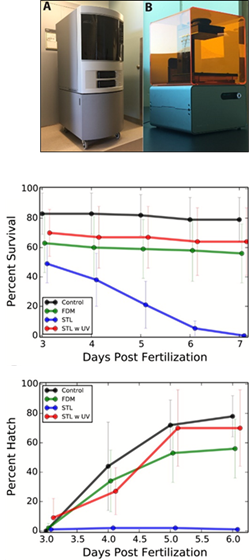

Images Top image: A is 3D FDM printer. B is a 3D STL printer. The middle graph shows the survival rates of exposed zebrafish embryos when compared to control unexposed embryos. The bottom graph shows the hatching rates of exposed zebrafish embryos when compared to control unexposed embryos.The zebrafish embryos are exposed to 3D-printed parts from a FDM and a STL printer. The STL printed parts when exposed to UV are less toxic when compared to the STL printed parts without UV treatment. Background 3D printing (3DP), or additive manufacturing, is the process of digitally fabricating products layer by layer using a 3D printer and a computer-generated blueprint. 3DP can be used in various industries including but not limited to aerospace, healthcare, consumer, automotive, and energy sectors. ATKearney consulting firm called 3DP a manufacturing revolution, and McKinsey Global Institute chose it as one of the twelve top economically disruptive technologies. The total economic impact of 3DP will reach to the level of $230-550 billion per year by 2025, and the global market for 3D printing is forecasted to be $17 billion in 2020 (25% CAGR from 2014 to 2020). Tech ID/UC Case 25962/2015-447-0 Related Cases 2015-447-0

美国